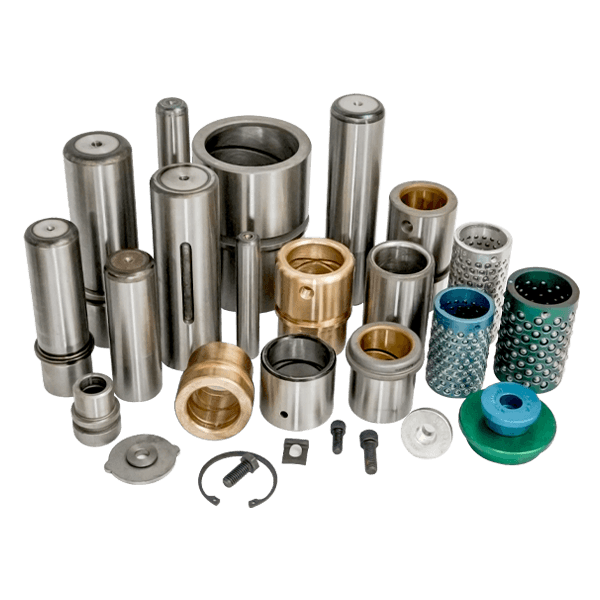

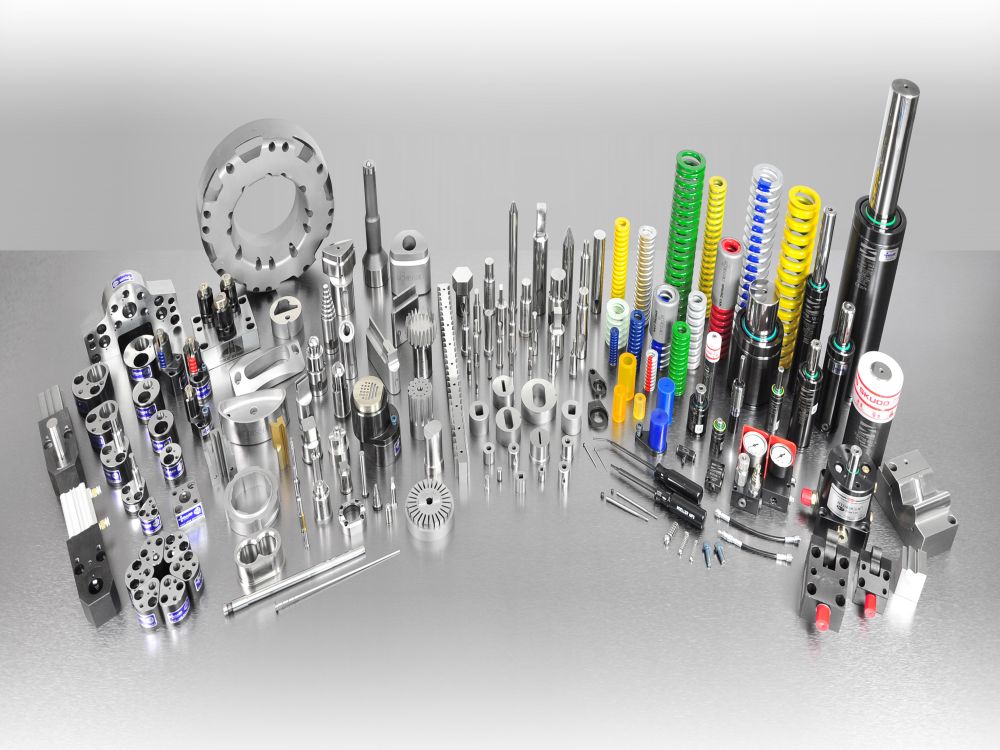

Die Set Components - Superior Components and Manufacturing Services

Superior Die Set Corporation has been making its own components for over 50 years, and we are the only die set manufacturer in the US that still does it in-house. We manufacture many standards as well as special components, which are frequently used to provide greater design flexibility when ... Superior Die Set Corporation has been making its own components for over 50 years, and we are the only die set manufacturer in the US that still does it in-house. We manufacture many standards as well as special components, which are frequently used to provide greater design flexibility when faced with adverse circumstances.