7 Key Benefits of Premium Mold Die Parts

- Enhanced Precision - Achieve tolerances within ±0.001" for critical applications

- Extended Tool Life - Premium materials increase die longevity by up to 300%

- Reduced Downtime - Superior quality parts minimize maintenance interruptions

- Cost Efficiency - Lower per-part costs through improved production rates

- Surface Quality - Exceptional finish reduces secondary operations

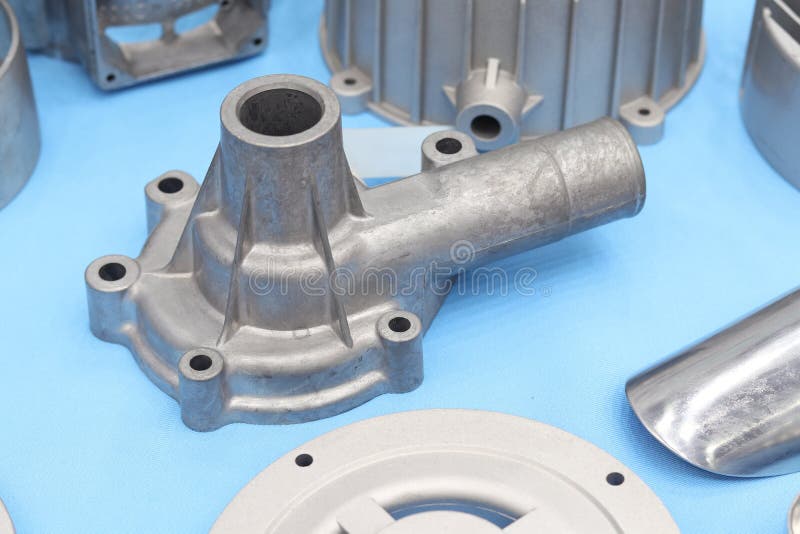

- Material Compatibility - Works with aluminum, zinc, magnesium, and specialty alloys

- Quick Turnaround - Faster delivery times for urgent production needs

Our precision-machined die parts undergo rigorous quality control processes, ensuring each component meets the highest industry standards for dimensional accuracy and surface integrity.